Electric motor control circuits are vital for ensuring the seamless operation of various equipment and devices. The start-stop switch wiring is a key component in these systems, offering both simplicity and safety for managing motor operations. Understanding how these circuits work can significantly enhance both performance and reliability, whether you’re new to electrical systems or an experienced professional. Dive into the essentials of start-stop switch wiring to equip yourself with practical insights and efficient wiring techniques.

- Learn how start-stop switch wiring enhances motor operation and safety.

- Discover the essential components and their roles within the control circuit.

- Uncover best practices for wiring and troubleshooting common issues.

By the end of this article, you will have a clearer understanding of how a well-configured start-stop switch setup can improve not only the operational efficiency of your systems but also their safety. Empower your skillset with these foundational insights and optimize your electrical installations for optimal performance.

Understanding Electric Motor Control Circuits and Their Impact on Start-Stop Switch Wiring

Electric motor control circuits are integral to industrial and commercial electrical systems, providing the means to manage motor functions efficiently. At the heart of these systems lies the start-stop switch wiring, a fundamental component ensuring operational command and safety.

The significance of the start-stop control circuit stems from its ability to provide users with immediate authority over motor operations. This intuitive mechanism allows for the precise activation and deactivation of motors, which is crucial in environments where precision and safety are paramount.

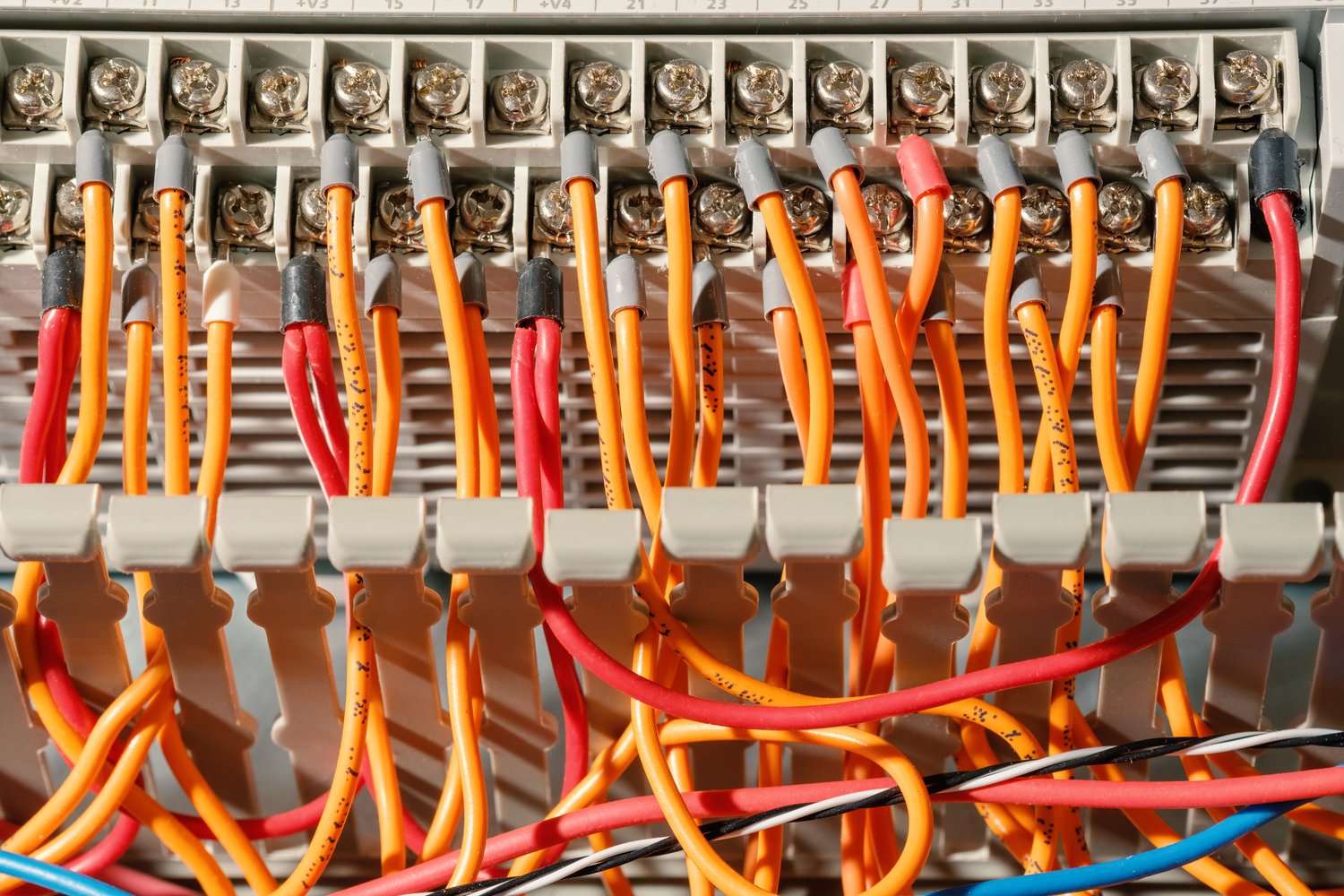

A typical control circuit includes components designed to manage electrical flow and respond appropriately to user inputs. Start-stop buttons, relays, and contactors work synergistically within this system, forming an efficient network that ensures reliable operation under various conditions.

Understanding the intricacies of start-stop switch wiring not only enhances the performance of electric motors but also minimizes risks associated with electrical malfunctions. Proper installation and maintenance of these circuits are vital to ensure operational longevity and safety, serving as a backbone for smooth motor function in diverse applications.

Components of Start-Stop Switch Wiring: Essential Elements and Their Functions

In the realm of electric motor control circuits, start-stop switch wiring comprises several critical components that work together to deliver a seamless user experience. Key among these are the start and stop buttons, which form the primary interface for interaction.

Start and Stop Buttons:

The starting point in any start-stop circuit, these buttons allow manual initiation and cessation of motor activity. Typically designed for durability, they ensure responsiveness under frequent use.

Contactors:

Contactors serve as electrically controlled switches that manage the high-current load, transferring power to the motor upon activation of the start button. They play a pivotal role in establishing and breaking the power circuit efficiently.

Relays:

Acting as control devices, relays facilitate the circuit’s response to the start-stop commands received. They help in directing the electric current to contactors and can also isolate the start-stop control circuit from high voltage components.

The synergy among these components fosters a proficient electrical environment. Each part, from buttons to contactors, has a specific role, contributing to the safe and effective functioning of motor control systems.

To maintain efficiency, understanding the layout and function of each element in start-stop switch wiring is imperative. This foundational knowledge assists in troubleshooting, ensuring quick resolution to potential issues and maintaining continuity in operations.

Best Practices for Wiring and Troubleshooting in Electric Motor Control Circuits: Start-Stop Switch Wiring Insights

Ensuring a reliable operation of motor systems hinges significantly on following best practices for wiring and troubleshooting. This not only enhances the functionality of the electric motor control circuits but also safeguards the system’s longevity.

When wiring a start-stop switch, always prioritize proper insulation and secure connections. This prevents short circuits and ensures consistent performance. Make sure to use suitable wiring gauges that match the motor’s power requirements. This reduces the risk of overheating and potential equipment damage.

A critical practice in start-stop switch wiring is the correct sequencing of terminal connections. Pay attention to the line (L), load (T), and control (C) terminals, ensuring they are securely fastened to avoid any miswiring, which could lead to malfunctioning.

Regular maintenance checks are essential. Always inspect for signs of wear or corrosion on switches and terminals. This proactive approach minimizes downtimes, particularly in commercial settings where uninterrupted motor operations are crucial.

In terms of troubleshooting techniques, one common issue encountered is the motor not starting despite the depression of the start button. This often signals an issue with the control circuit. Verify the control circuit voltage using a multimeter, ensuring that there is no open circuit in the wiring.

Another frequent challenge includes experiencing sudden motor trips. This can be attributed to overload conditions. Check the thermal overload relay settings and adjust them to match the motor’s specifications.

If the issue persists, examine the integrity of the stop button. A malfunctioning stop button can prevent the motor from sustaining operation after the start button is released. Replacing faulty components promptly can restore reliable function.

By adhering to these wiring best practices and troubleshooting guidelines, users can enhance operational efficiency and safety. Keeping start-stop switch wiring in optimal condition ensures business continuity, a vital aspect for any operation relying on electric motor control circuits.

Frequently Asked Questions About Start-Stop Switch Wiring in Electric Motor Control Circuits

What is the role of a start-stop switch in motor control circuits?

Role: It controls the activation and deactivation of the motor, ensuring operational efficiency and safety.

What are the essential components of start-stop switch wiring?

Components include: Start button, stop button, circuit breaker, contactor, and overload relay.

Why is proper wiring essential for start-stop switches?

Importance: Ensures reliable motor operation and prevents damage or safety hazards.

How can I troubleshoot common issues in start-stop switch wiring?

Troubleshooting tips: Check connections, inspect for damage, test components for continuity, and verify power supply.

What are best practices for maintaining start-stop switch wiring?

- Regular inspections

- Ensure secure connections

- Replace worn components

- Follow manufacturer guidelines