Understanding cable types for various applications

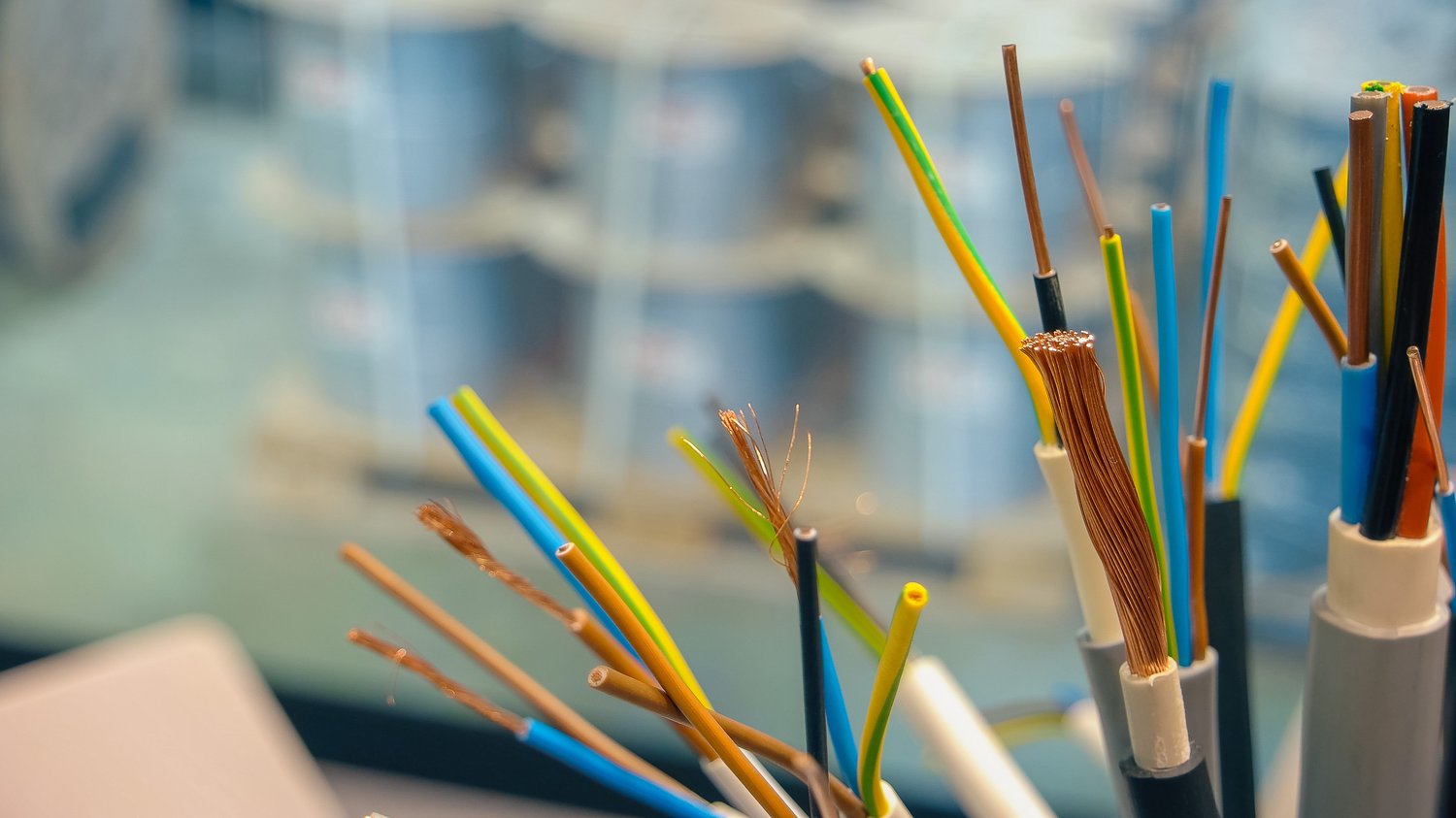

Electrical projects require careful consideration when selecting cables. Different applications demand specific cable types to ensure safety and efficiency. Cables for mobile receivers are essential for portable devices and equipment. These cables must withstand frequent movement and potential environmental stresses. Crane cables, designed for heavy-duty lifting operations, need to be exceptionally durable. They typically feature reinforced insulation and protective sheaths. Welding cables are specialized conductors that carry high currents for welding processes. These cables are usually more flexible and heat-resistant than standard electrical cables.

Cables in rubber insulation offer excellent flexibility and resistance to various environmental factors. They are commonly used in outdoor applications or areas exposed to moisture and chemicals. Cables in rubber insulation can withstand temperatures ranging from -40°C to 90°C. Wires in PVC insulation are popular for general-purpose electrical installations. PVC insulation provides good electrical properties and fire resistance. These wires are suitable for both residential and commercial applications. Understanding these cable types helps in making informed decisions for your electrical projects.

Selecting the right cable size and capacity

Choosing the correct cable size is crucial for electrical safety and efficiency. The American Wire Gauge (AWG) system is commonly used to measure cable thickness. Lower AWG numbers indicate thicker cables. For example, a 12 AWG cable is thicker than a 14 AWG cable. Cable capacity refers to the maximum current a cable can safely carry. This capacity is influenced by factors such as conductor material, insulation type, and ambient temperature. A typical 12 AWG copper wire can safely carry up to 20 amperes in residential applications.

Overloading cables can lead to overheating and potential fire hazards. It’s essential to calculate the total load of connected devices before selecting a cable. For instance, a 1500-watt appliance running on a 120-volt circuit requires a minimum of 12.5 amperes. Always choose a cable rated higher than your calculated load. Crane cables often require larger sizes due to their high-load applications. These cables may use sizes up to 4/0 AWG or larger, depending on the specific crane requirements.

Importance of proper insulation and sheathing

Insulation and sheathing play crucial roles in cable performance and safety. Insulation materials electrically separate conductors and protect against current leakage. Common insulation materials include PVC, rubber, and cross-linked polyethylene (XLPE). Each material offers different properties suited to specific applications. For example, XLPE insulation can withstand higher temperatures, up to 90°C in some cases. This makes it suitable for high-load industrial applications.

Sheathing provides mechanical protection and additional insulation for cables. It shields against environmental factors such as moisture, UV radiation, and physical damage. Wires in PVC insulation often feature a PVC sheath for added protection. Rubber-sheathed cables offer excellent flexibility and are commonly used in portable applications. Some specialized cables, like those used in marine environments, may have additional protective layers. These layers can include metal braids or foil shields to prevent electromagnetic interference.

Considering environmental factors in cable selection

Environmental conditions significantly impact cable performance and lifespan. Temperature extremes can affect insulation properties and conductor resistance. Cables rated for high temperatures, such as those used in industrial ovens, may use special materials like silicone rubber insulation. These cables can withstand temperatures up to 200°C. In contrast, cables for cold environments need to remain flexible at low temperatures. Some Arctic-grade cables can operate at temperatures as low as -50°C.

Moisture exposure is another critical factor in cable selection. Cables installed underground or in wet locations require special waterproofing measures. These may include water-blocking tapes or gels within the cable construction. UV radiation can degrade certain types of cable insulation over time. Cables for mobile receivers often need UV-resistant sheathing for outdoor use. Chemical exposure is also a consideration in industrial settings. Cables in chemical plants may require special fluoropolymer insulation to resist corrosive substances.

Safety standards and certifications for electrical cables

Adhering to safety standards is crucial when selecting electrical cables. In the United States, the National Electrical Code (NEC) provides guidelines for cable usage in various applications. The Underwriters Laboratories (UL) certification is widely recognized for electrical product safety. UL-listed cables have undergone rigorous testing to meet specific safety criteria. In Europe, the CE marking indicates compliance with EU safety standards.

Different cable types have specific certifications based on their intended use. For example, Welding cables often require compliance with standards set by the American Welding Society (AWS). Marine cables may need to meet standards set by organizations like the American Bureau of Shipping (ABS). It’s essential to verify that the cables you choose meet all relevant safety standards and certifications for your specific application. This ensures not only compliance with regulations but also the safety and reliability of your electrical installation.