Understanding fuse links type D0

Fuse links type D0 are crucial components in electrical systems. These devices protect circuits from overloads and short circuits. They come in various amperage ratings, typically ranging from 2 to 100 amperes. D0 fuse links are compact, measuring approximately 15mm in diameter. Their small size makes them ideal for residential and light commercial applications. [fuse links type D0] https://onninen.pl/en/products/Electrotechnics/Fuse-links-accessories/Fuse-links-type-D0 are designed to fit into specific fuse holders. This ensures proper installation and function.

The D0 system offers several advantages. It provides reliable overcurrent protection. These fuses react quickly to fault conditions, typically within milliseconds. They are also cost-effective, with prices ranging from $1 to $5 per fuse. D0 fuses have a long service life, often lasting 10 years or more under normal conditions. Their standardized design allows for easy replacement and maintenance.

When selecting D0 fuse links, consider the circuit’s amperage requirements. Choose a fuse rated slightly higher than the expected current draw. For example, a 20A circuit might use a 25A fuse. Always consult local electrical codes for specific requirements. Remember to use fuses from reputable manufacturers to ensure quality and safety. Proper storage is essential; keep fuses in a dry, cool place to maintain their integrity.

Exploring Fuse links accessories

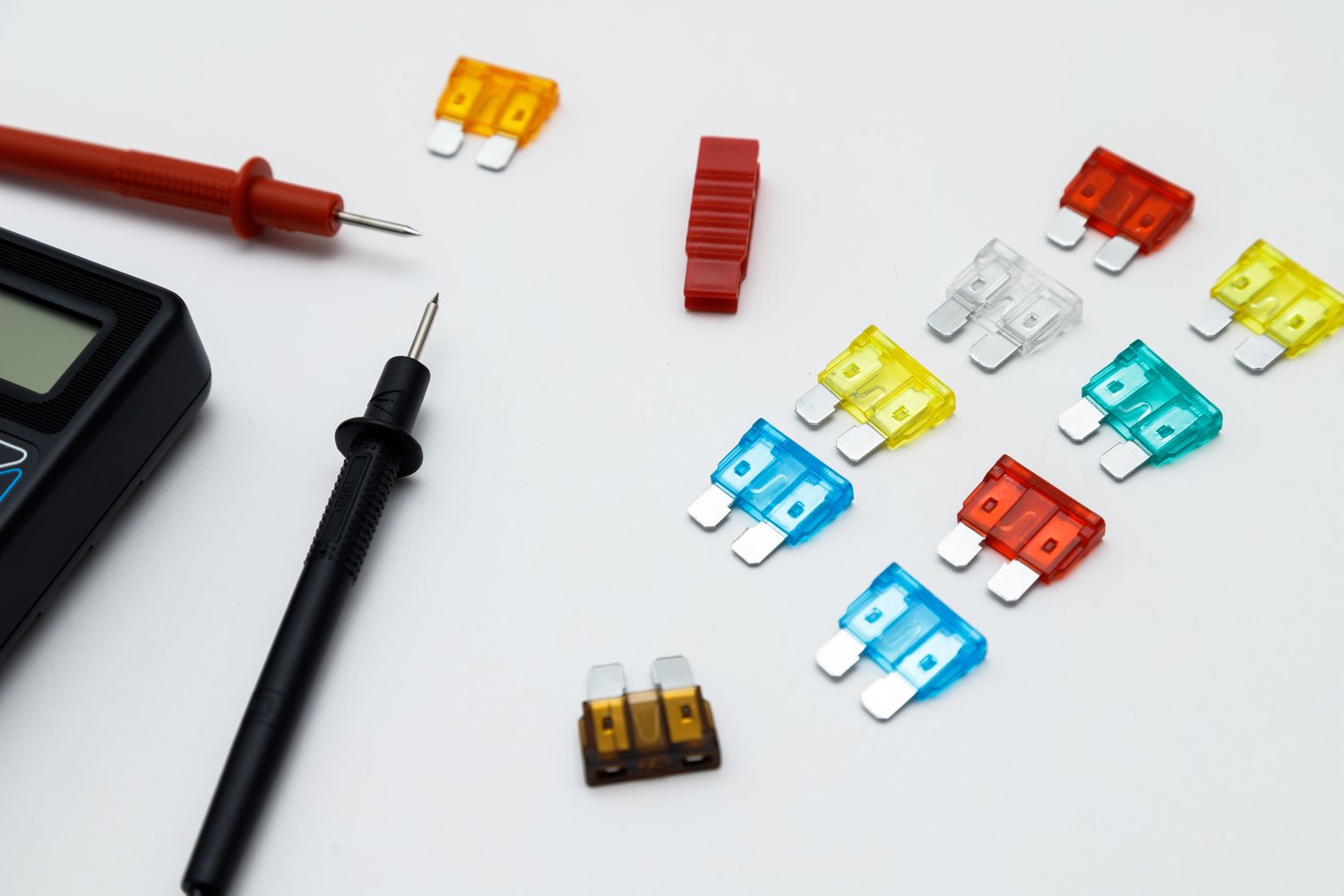

Fuse links accessories enhance the functionality and safety of fuse systems. These include fuse holders, bases, and disconnectors. Fuse holders securely contain the fuse and provide easy access for replacement. They come in various sizes to accommodate different fuse types. Prices for fuse holders range from $5 to $20, depending on the design and amperage rating. [Fuse links accessories] https://onninen.pl/en/products/Electrotechnics/Fuse-links-accessories also include tools for safe fuse removal and installation.

Fuse bases provide a mounting point for fuses in electrical panels. They are available in single-pole and multi-pole configurations. Multi-pole bases can accommodate up to four fuses, ideal for three-phase systems. Bases typically cost between $10 and $30, based on their capacity and features. Some bases include indicators that show when a fuse has blown, simplifying troubleshooting.

Disconnectors are safety devices that isolate fused circuits. They allow for safe maintenance and fuse replacement. Disconnectors can handle currents up to 630 amperes in some models. Prices for disconnectors start at $50 and can exceed $200 for high-capacity units. When selecting accessories, ensure compatibility with your fuse system. Consider factors such as voltage rating, current capacity, and environmental conditions.

Importance of proper Electrotechnics in fuse systems

Electrotechnics plays a vital role in fuse system design and implementation. This field encompasses the principles of electrical engineering applied to practical applications. Proper electrotechnical design ensures the safety and efficiency of electrical systems. It involves calculating load requirements, selecting appropriate components, and adhering to industry standards. [Electrotechnics] https://onninen.pl/en/products/Electrotechnics also covers the study of electrical phenomena, which is crucial for understanding fuse operation.

In fuse system design, electrotechnical considerations include voltage drop calculations. These calculations help determine the correct fuse size and wire gauge. For example, a 100-foot run of 12 AWG wire at 20 amperes experiences a voltage drop of about 3.4%. Electrotechnicians also assess short-circuit currents, which can reach thousands of amperes. This information is critical for selecting fuses with adequate interrupting ratings.

Proper electrotechnical practices extend to installation and maintenance. This includes using the correct tools and techniques for fuse replacement. It also involves regular system inspections, typically recommended annually. During inspections, technicians check for signs of overheating or corrosion. They also verify that fuse ratings match the system requirements. By following electrotechnical best practices, businesses can reduce downtime and improve safety.

Best practices for fuse system maintenance

Regular maintenance is essential for the longevity and reliability of fuse systems. Establish a maintenance schedule based on system usage and environmental factors. For most commercial applications, quarterly inspections are recommended. During these checks, visually inspect fuses and accessories for signs of damage or wear. Look for discoloration, which may indicate overheating. Check connections to ensure they are tight and free from corrosion.

Keep detailed records of fuse replacements and system modifications. This information helps identify patterns and potential issues. Use a log book or digital system to track maintenance activities. Include details such as date, technician name, and work performed. When replacing fuses, always use the correct type and rating. Mixing fuse types can compromise system safety and performance. Stock commonly used fuses to minimize downtime during replacements.

Thermal imaging can be a valuable tool in fuse system maintenance. Annual thermal scans can detect hot spots before they cause failures. These scans typically cost between $500 and $1,500, depending on system size. Consider investing in fuse monitors for critical systems. These devices provide real-time status updates and can alert maintenance personnel to potential issues. Proper maintenance not only enhances safety but can also extend the life of your electrical system by up to 25%.

Choosing the right fuse for your application

Selecting the appropriate fuse is crucial for system protection and efficiency. Consider the following factors when choosing fuses:

- Voltage rating: Must match or exceed the system voltage

- Current rating: Should be slightly higher than the normal operating current

- Interrupting capacity: Must be higher than the available fault current

- Time-current characteristics: Determine how quickly the fuse responds to overloads

- Physical size and type: Must fit the existing fuse holder or base

For specific applications, consult industry standards and local codes. For example, UL 248 provides guidelines for low-voltage fuses in North America. In Europe, IEC 60269 is the relevant standard. These documents specify requirements for fuse performance and testing. When in doubt, consult with a qualified electrician or engineer to ensure proper fuse selection.

Consider the environment where the fuse will be installed. Factors such as temperature, humidity, and vibration can affect fuse performance. For outdoor applications, choose fuses rated for harsh conditions. In industrial settings, consider fuses with high cycling capacity. These can withstand frequent on-off cycles without premature failure. By selecting the right fuse, you can optimize system protection and minimize unnecessary downtime.