Understanding External Installations in Construction

External Installations play a crucial role in modern building design and functionality. These systems encompass a wide range of components that connect structures to utility networks and manage outdoor environments. Common examples include drainage systems, outdoor lighting, and irrigation networks. External Installations are essential for maintaining building integrity, ensuring proper water management, and enhancing outdoor spaces. They require careful planning and expert installation to function effectively. Proper maintenance of these systems can significantly extend their lifespan and improve overall property value. [External Installations] https://onninen.pl/en/products/External-Installations are subject to various regulations and standards that ensure safety and efficiency.

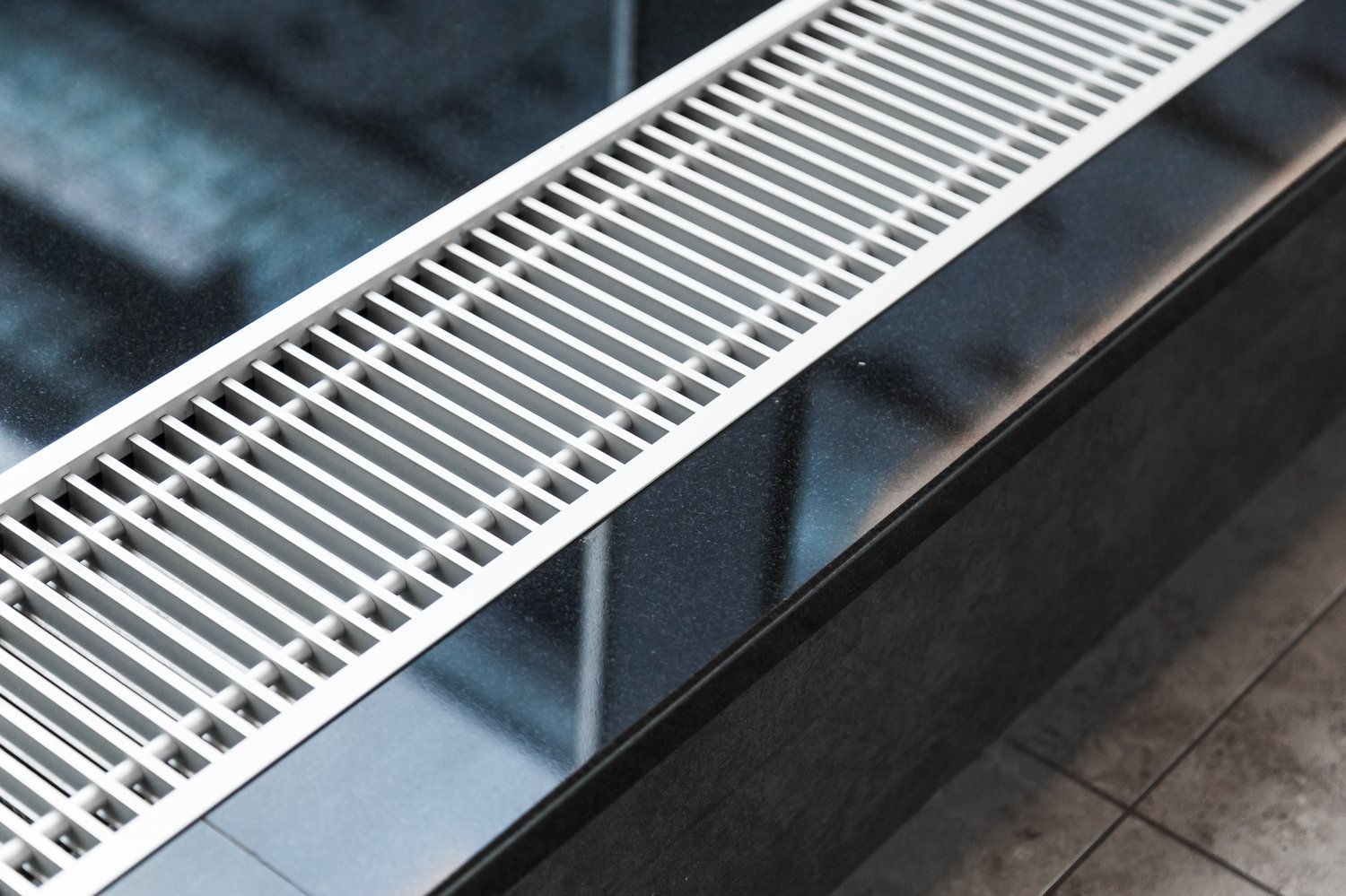

The Importance of External Linear Drains

External linear drains are vital components in managing surface water around buildings. These long, narrow drainage channels efficiently collect and divert rainwater and runoff. They are typically installed along the perimeter of structures or in areas prone to water accumulation. Linear drains come in various materials, including stainless steel, polymer concrete, and PVC. The choice of material depends on factors such as load-bearing requirements and environmental conditions. Proper sizing of exernal linear drains is crucial, with calculations based on expected rainfall intensity and drainage area. [exernal linear drains] https://onninen.pl/en/products/External-Installations/External-linear-drains contribute significantly to preventing water damage and maintaining dry, safe outdoor spaces.

Selecting the Right External Linear Drain

Choosing the appropriate external linear drain involves several considerations. The first factor is the expected water volume, which determines the required channel width and depth. Load class is another crucial aspect, ranging from pedestrian areas (Class A15) to heavy industrial zones (Class F900). Grate design affects both aesthetics and functionality, with options including slot drains and decorative patterns. Material selection impacts durability and maintenance needs, with stainless steel offering excellent corrosion resistance. Installation location influences the drain’s slope and connection to the main drainage system. Professional advice is recommended to ensure the selected drain meets all specific project requirements.

Installation Best Practices for External Linear Drains

Proper installation of external linear drains is essential for their effectiveness and longevity. The process begins with accurate site surveying and planning to determine optimal drain placement. Excavation depth should allow for a stable base, typically 100-150mm below the finished surface level. A concrete bed, usually 100mm thick, provides a solid foundation for the drain channel. Precise leveling is crucial to ensure proper water flow and prevent pooling. Connections to the main drainage system must be watertight to prevent leaks. Backfilling around the drain should be done carefully to avoid damage or misalignment. Final surfacing, whether concrete, asphalt, or pavers, must be finished flush with the drain grate. Regular inspections during installation help catch and correct any issues promptly.

Maintenance and Care of External Installations

Regular maintenance is key to the longevity and efficiency of external installations. For linear drains, this includes periodic cleaning to remove debris and sediment. Inspections should be conducted at least twice a year, with additional checks after severe weather events. Grates should be removed and channels cleaned using high-pressure water jets when necessary. Damaged components, such as cracked channels or worn grates, should be replaced promptly. For other external installations, maintenance might involve checking electrical connections, lubricating moving parts, or updating control systems. Keeping detailed maintenance records helps track system performance and plan for future upgrades. Professional servicing is recommended for complex systems to ensure all components function optimally.