Understanding protective strips in electrical installations

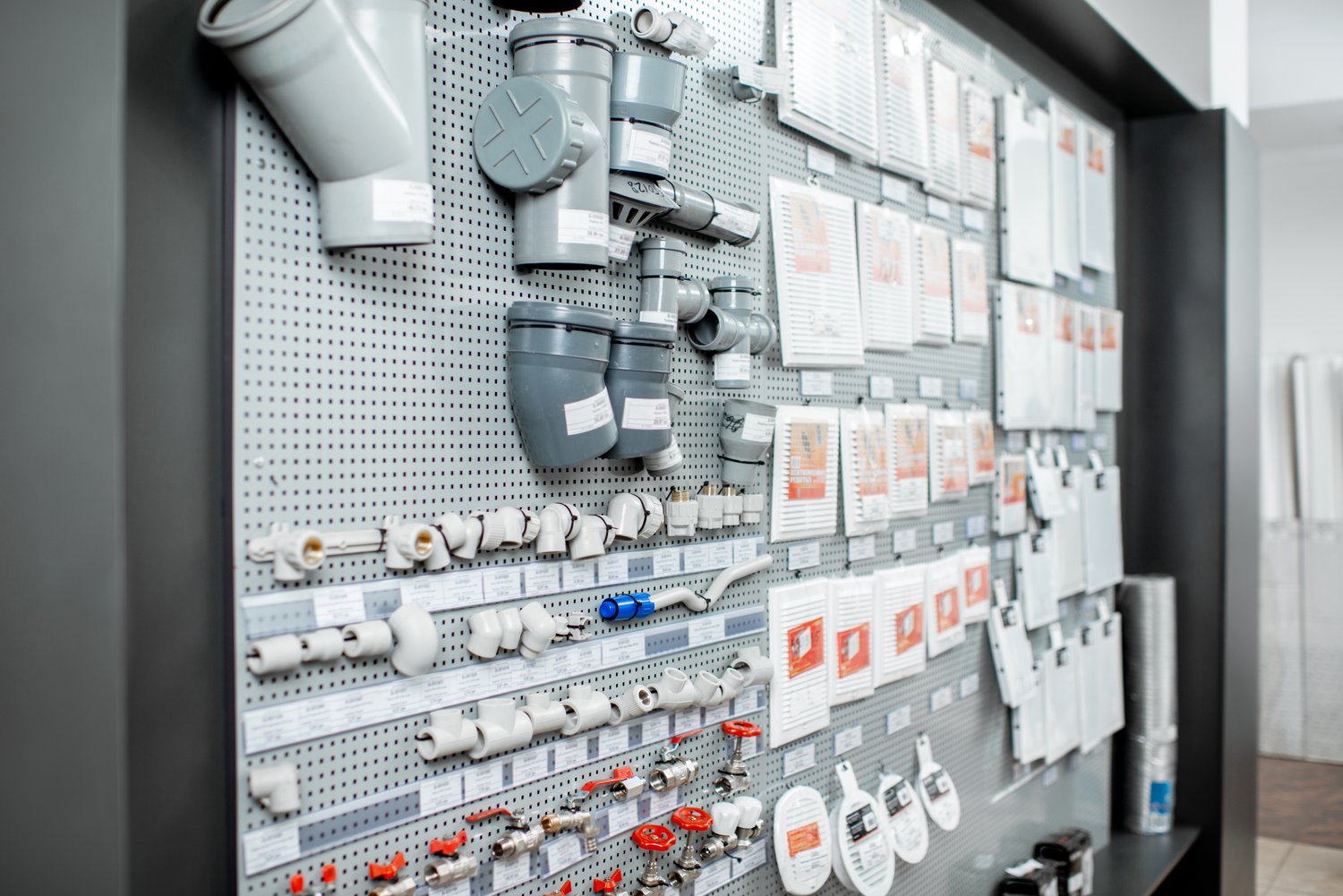

Protective strips serve as crucial safety components in electrical panels and switchboards. These elements shield terminal blocks and connections from accidental contact while maintaining proper insulation between different voltage levels. Electrical contractors typically install them in distribution boards where multiple circuits converge. Most protective strips feature durable plastic construction that withstands temperatures up to 85 degrees Celsius. Their standardized dimensions ensure compatibility with various terminal block manufacturers across the industry.

Professional electricians choose protective strips https://onninen.pl/en/products/Electrotechnics/Switchgears-and-enclosures/Equipment-and-accessories/Protective-strips based on specific installation requirements. Width options range from 6mm to 12mm to accommodate different terminal spacing configurations. These components prevent arc formation between adjacent terminals during switching operations. Installation involves simple snap-on mounting that requires no additional tools or fasteners. Quality protective strips maintain their mechanical properties for over 20 years in normal operating conditions.

Color coding helps technicians identify different circuit types within complex electrical panels. Standard colors include gray for neutral connections and green for earth terminals. Some manufacturers offer transparent versions that allow visual inspection of underlying connections. These strips also provide protection against dust and moisture in industrial environments. Their flame-retardant properties meet stringent safety standards including IEC 60947-7-1 specifications.

Proper spacing between protective strips ensures adequate ventilation within electrical enclosures. Minimum clearance requirements typically specify 5mm between adjacent protective elements. This spacing prevents heat buildup that could compromise insulation materials over time. Regular inspection schedules should include checking these components for cracks or discoloration. Replacement becomes necessary when protective strips show signs of thermal damage or mechanical wear.

Terminal list systems for organized circuit management

Terminal list systems revolutionize how electrical professionals document and organize circuit connections. These comprehensive labeling solutions provide clear identification for every terminal point within control panels and distribution boards. Modern systems include pre-printed numbers that correspond to detailed wiring diagrams and technical documentation. Installation teams can reduce wiring errors by up to 60% when using properly implemented terminal list systems. Each label withstands industrial cleaning solvents and maintains legibility for decades.

Eaton manufactures industry-leading terminal identification solutions that streamline maintenance procedures. Their terminal list (IKA) Eaton https://onninen.pl/en/product/EATON-Terminal-list-IKA-N-PE-3-36-IKA-174174,161350 products feature consecutive numbering from 1 to 50 on individual strips. These labels attach securely to terminal blocks without interfering with electrical connections. Heat resistance extends to 105 degrees Celsius for applications in demanding industrial environments. Professional electricians appreciate the clear font that remains readable even in poor lighting conditions.

Customization options allow electrical contractors to match terminal lists with specific project requirements. Standard configurations include neutral and protective earth designations alongside numerical sequences. Some systems incorporate color-coding that corresponds to different voltage levels within the same panel. Digital printing technology ensures consistent quality across large installation projects. These identification systems comply with international standards including IEC 60445 for electrical equipment marking.

Maintenance efficiency improves significantly when technicians can quickly locate specific terminals during troubleshooting procedures. Well-organized terminal lists reduce service call duration by approximately 30% compared to unlabeled installations. Documentation becomes more accurate when physical labels match electrical drawings precisely. Quality assurance processes benefit from clear identification that allows systematic verification of connections. Long-term reliability depends on choosing terminal lists that maintain adhesion and legibility throughout the equipment lifecycle.

Electrotechnics fundamentals for wholesale customers

Electrotechnics encompasses the comprehensive study and application of electrical components in modern installations. This field covers everything from basic wiring accessories to sophisticated control systems used in industrial automation. Wholesale customers benefit from understanding fundamental principles that govern electrical component selection and application. Market demand for electrotechnical products grows by 8% annually as buildings incorporate more advanced electrical systems. Professional installation requires components that meet strict quality standards and regulatory requirements.

Component compatibility becomes critical when designing electrical installations that integrate multiple manufacturer products. Standard mounting dimensions ensure that terminal blocks, protective strips, and identification systems work together seamlessly. Quality electrotechnics https://onninen.pl/en/products/Electrotechnics/ suppliers maintain extensive inventory levels to support complex project requirements. Technical support teams help contractors select appropriate components for specific voltage and current ratings. Bulk purchasing options provide cost advantages for larger electrical installation projects.

Safety regulations drive continuous innovation in electrotechnical component design and manufacturing. New materials offer improved flame resistance while maintaining excellent electrical insulation properties. Environmental considerations influence product development toward more sustainable manufacturing processes. Testing protocols verify component performance under extreme temperature and humidity conditions. Certification marks indicate compliance with regional safety standards including CE marking for European markets.

Future trends in electrotechnics focus on smart building integration and renewable energy applications. Components must accommodate increasing data communication requirements alongside traditional power distribution functions. Modular design approaches allow flexible system expansion as building needs evolve. Quality wholesale partnerships provide access to emerging technologies before they become mainstream market requirements. Professional training programs ensure that installation teams understand proper application techniques for new electrotechnical products.

Best practices for component selection and installation

Selecting appropriate electrical components requires careful consideration of environmental conditions and performance requirements. Temperature ratings must exceed maximum expected operating conditions by at least 20% to ensure reliable long-term performance. Humidity levels in installation locations influence material selection for terminal blocks and protective components. Chemical exposure assessments help identify components with appropriate resistance to cleaning agents and industrial atmospheres. Vibration resistance becomes important in applications near mechanical equipment or transportation corridors.

Installation procedures significantly impact component reliability and system safety throughout the operational lifetime. Proper torque specifications prevent loose connections that could generate dangerous heat buildup. Sequential installation following manufacturer guidelines ensures optimal performance of integrated component systems. Quality control inspections verify correct placement and orientation of protective strips and identification labels. Documentation requirements include recording component serial numbers and installation dates for maintenance tracking purposes.

Maintenance schedules should include regular inspection of all electrotechnical components within distribution systems. Visual checks identify signs of overheating, mechanical damage, or environmental degradation before failures occur. Thermal imaging surveys detect hot spots that indicate developing connection problems. Cleaning procedures remove accumulated dust and debris that could compromise insulation effectiveness. Replacement intervals depend on component type and operating environment severity.

Cost optimization strategies balance initial component costs with long-term reliability and maintenance requirements. Premium components often provide better value through extended service life and reduced maintenance needs. Standardization programs simplify inventory management while ensuring compatibility across multiple installation projects. Vendor relationships with established electrotechnical suppliers provide access to technical support and training resources. Bulk purchasing agreements can reduce component costs by 15-25% compared to individual project procurement.