Understanding cable protection systems in modern installations

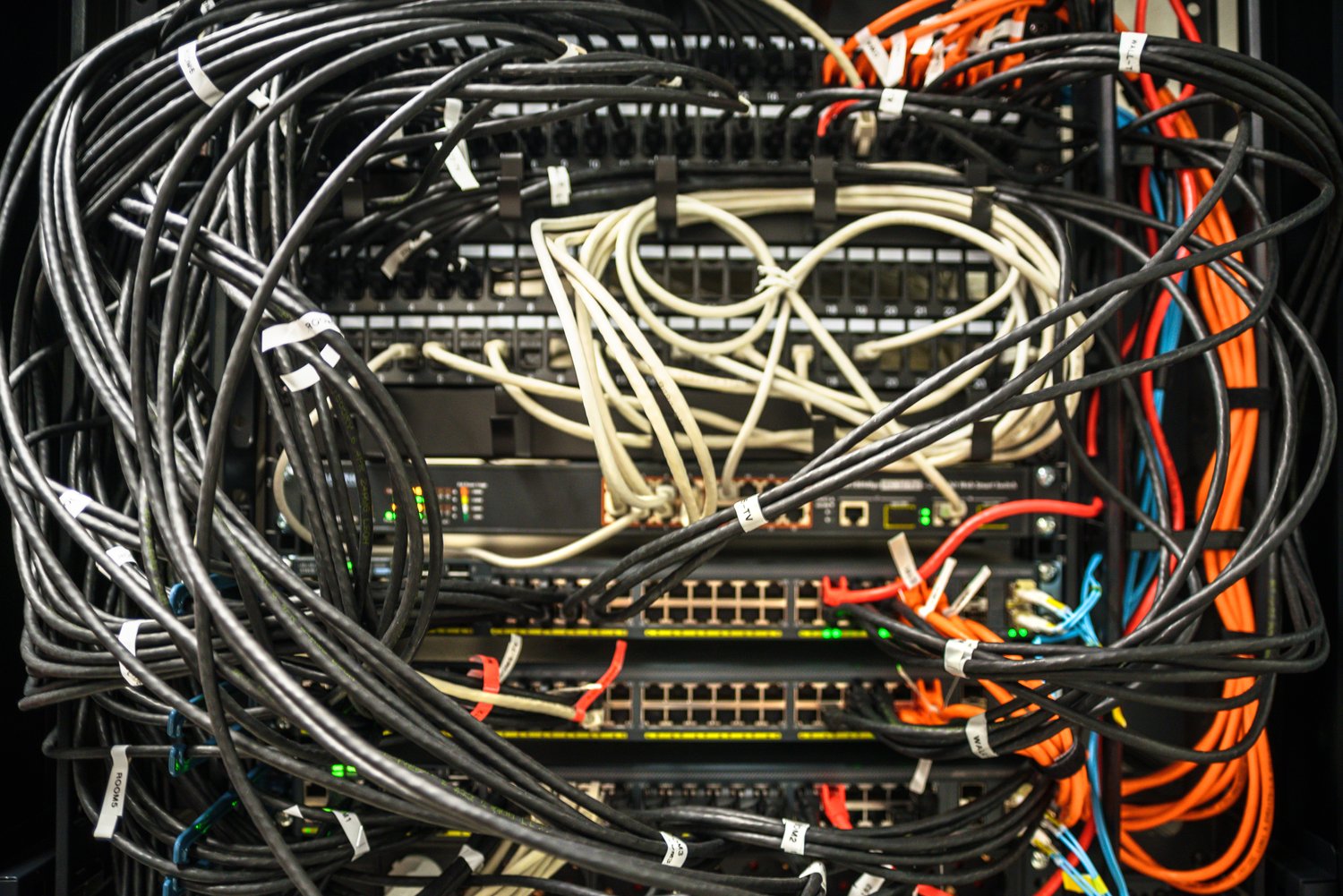

Energetics systems require proper cable management to ensure safety and reliability in electrical installations. Modern buildings demand sophisticated protection methods that shield cables from environmental damage and mechanical stress. Professional electricians rely on specialized components to create durable pathways for electrical connections throughout commercial and residential structures.

Cable wells serve as crucial junction points where multiple electrical lines converge and branch out to different areas. These underground or embedded chambers protect connections from moisture, debris, and accidental damage during construction or maintenance work. Their strategic placement allows easy access for future modifications while maintaining system integrity over decades of operation.

Proper sizing calculations determine the success of any cable management project before installation begins. A standard residential installation typically requires wells with 600mm diameter openings for main distribution points. Commercial projects often need larger chambers measuring 1200mm or more to accommodate multiple high-voltage feeders and communication cables in separate compartments.

Material selection and durability considerations

High-quality materials ensure long-term performance in demanding electrical environments where temperature fluctuations and chemical exposure occur regularly. Polymer-based systems resist corrosion better than traditional metal alternatives and maintain structural integrity for 25 years or longer. These advanced materials also provide superior insulation properties that prevent electrical faults and reduce maintenance requirements significantly.

Professional-grade Energetics installations demand components that meet strict industry standards for fire resistance and mechanical strength. Certified products undergo rigorous testing procedures that simulate decades of real-world conditions including freeze-thaw cycles, chemical exposure, and mechanical loading. Installation teams can trust these verified components to perform reliably throughout their intended service life without premature failure.

Temperature ratings play a critical role in component selection since electrical systems generate heat during normal operation cycles. Standard installations operate within -20°C to +60°C ranges, while specialized applications may require materials rated for extreme conditions up to +90°C. Proper temperature matching prevents thermal expansion problems that could compromise sealing effectiveness or cause structural damage over time.

Installation best practices and common applications

Foundation preparation requires careful attention to drainage and soil conditions before installing permanent cable wells in outdoor locations. Excavation depth should extend 200mm below the frost line to prevent heaving damage during winter months. Proper bedding material consisting of 150mm compacted sand provides stable support and allows for thermal expansion without creating stress points.

Concrete and fittings work together to create watertight seals that protect electrical connections from environmental hazards throughout their operational lifetime. Professional installers use expanding foam gaskets and rubber sealing rings to eliminate potential leak paths around cable entry points. These sealing methods prevent water infiltration that could cause short circuits or equipment damage in critical electrical systems.

Quality Concrete and fittings ensure secure connections that withstand mechanical stress and environmental challenges for decades of reliable service. Standard installations require Grade C30 concrete mix with 150mm minimum wall thickness for adequate structural protection. Reinforcement bars spaced at 200mm intervals provide additional strength against soil movement and surface loading from vehicles or equipment.