Understanding sewer connection fundamentals

Sewer connections form the backbone of any effective wastewater management system. These vital components link your property’s drainage network to the main municipal sewer line. Proper installation requires careful planning and adherence to local building codes. Most residential properties need connections ranging from 100mm to 150mm in diameter. Commercial buildings often require larger pipes, typically 200mm to 300mm, depending on their usage requirements.

The connection process involves several critical steps that demand professional expertise. First, you must obtain proper permits from your local authority before beginning any excavation work. Second, the connection point must be precisely located to avoid damaging existing utilities. Third, the pipe gradient should maintain a minimum slope of 1:40 to ensure proper flow. Fourth, backfill materials must be carefully selected and compacted to prevent future settling issues.

Quality materials make a significant difference in system longevity and performance. PVC pipes offer excellent durability and typically last 50 to 100 years when properly installed. Clay pipes, while traditional, may crack over time and generally last 25 to 50 years. Modern HDPE pipes provide superior flexibility and can withstand ground movement better than rigid alternatives. Sewer connections https://onninen.pl/en/products/External-Installations/External-sewerage/Gravity-sewer/Sewer-connections require specialized fittings to ensure watertight joints and prevent root intrusion.

Inspection chambers play a crucial role in maintaining your sewer connection system effectively. These access points allow for regular cleaning and maintenance of the pipeline network. Standard chambers typically measure 1200mm in diameter for residential applications. Larger commercial installations may require chambers up to 1800mm wide to accommodate maintenance equipment. Installing chambers at strategic locations, particularly at changes in direction or gradient, helps identify potential blockages quickly and reduces repair costs significantly.

Gravity sewer system design principles

Gravity sewer systems rely on natural slope and gravitational force to move wastewater efficiently. These systems represent the most cost-effective solution for most residential and commercial applications. Proper design requires calculating the correct pipe diameter based on expected flow rates and peak usage periods. A typical household generates approximately 200 to 300 liters of wastewater daily. This volume increases significantly in commercial settings, where restaurants may produce 40 liters per seat per day.

Slope calculations form the foundation of effective gravity sewer design and installation. The minimum gradient for 100mm pipes should be 1:40, while 150mm pipes can function with a 1:60 slope. Steeper gradients, up to 1:10, may be necessary in challenging terrain or where space constraints exist. However, excessive slope can cause problems, including pipe erosion and solids separation from liquids. Professional engineers use specialized software to calculate optimal gradients for complex installations involving multiple elevation changes.

Pipe sizing depends on several factors, including flow velocity, capacity requirements, and future expansion plans. Undersized pipes lead to frequent blockages and system backups that are expensive to resolve. Oversized pipes may not maintain adequate flow velocity, allowing solids to settle and accumulate over time. Standard residential connections typically use 100mm to 150mm diameter pipes, while commercial applications often require 200mm to 400mm pipes. Gravity sewer https://onninen.pl/en/products/External-Installations/External-sewerage/Gravity-sewer systems must maintain flow velocities between 0.6 and 3.0 meters per second for optimal performance.

Ventilation systems prevent dangerous gas buildup and maintain proper pressure within the pipeline network. Each branch connection requires adequate ventilation to function correctly and safely. Vent pipes typically measure 50mm to 100mm in diameter and extend above the roofline. They should terminate at least 900mm above any opening window or door to prevent odors from entering buildings. Multiple vents may be necessary for large commercial installations or extended pipe runs exceeding 50 meters in length.

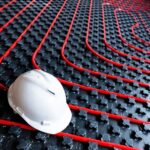

External sewerage installation best practices

External sewerage systems require careful excavation planning to ensure worker safety and system integrity. Trenches must be properly shored when they exceed 1.2 meters in depth to prevent cave-ins. The excavation width should allow adequate working space, typically 600mm on each side of the pipe. Groundwater management becomes critical in wet conditions, often requiring dewatering pumps to maintain dry working conditions. Utility location services must mark all existing services before any excavation begins to prevent costly accidents and service disruptions.

Bedding and backfill materials significantly impact long-term system performance and durability. The pipe bedding should consist of granular material, typically 10mm graded stone or sand, extending 150mm below and around the pipe. This support layer distributes loads evenly and prevents point loading that could crack the pipe. Backfill should be placed and compacted in 300mm lifts to achieve proper density without damaging the installed pipes. Poor compaction leads to settlement issues that can cause pipe misalignment and joint failure over time.

Joint sealing techniques vary depending on the pipe material and connection type used. Rubber ring joints provide excellent sealing for PVC pipes when properly installed and lubricated. Push-fit connections offer convenience but require careful alignment to prevent seal damage during assembly. Welded joints, while more expensive, provide superior long-term reliability for critical applications. External sewerage https://onninen.pl/en/products/External-Installations/External-sewerage systems must undergo pressure testing before backfilling to verify joint integrity and identify any installation defects early.

Testing and commissioning procedures ensure your new sewer system meets design specifications and regulatory requirements. Pressure testing typically involves filling the system with water and maintaining 1.5 times the working pressure for 15 minutes. CCTV surveys provide detailed internal inspection of installed pipes to identify alignment issues or debris. Flow testing verifies that the system can handle design capacity without backup or overflow. Documentation of all tests and inspections is essential for warranty claims and future maintenance planning purposes.