Understanding pneumatic tools

Pneumatic tools are powered by compressed air, offering high performance and efficiency. These devices are widely used in electrical and plumbing industries. They provide significant advantages over traditional hand tools. Pneumatic tools include nailers, staplers, drills, and impact wrenches. These instruments can significantly increase productivity and reduce worker fatigue.

Benefits of using pneumatic tools

Pneumatic tools offer numerous advantages in various applications. They are lightweight, making them easy to handle for extended periods. These tools provide consistent power output, ensuring uniform results. Pneumatic tools are also more durable than their electric counterparts. They require less maintenance and have a longer lifespan, reducing overall costs.

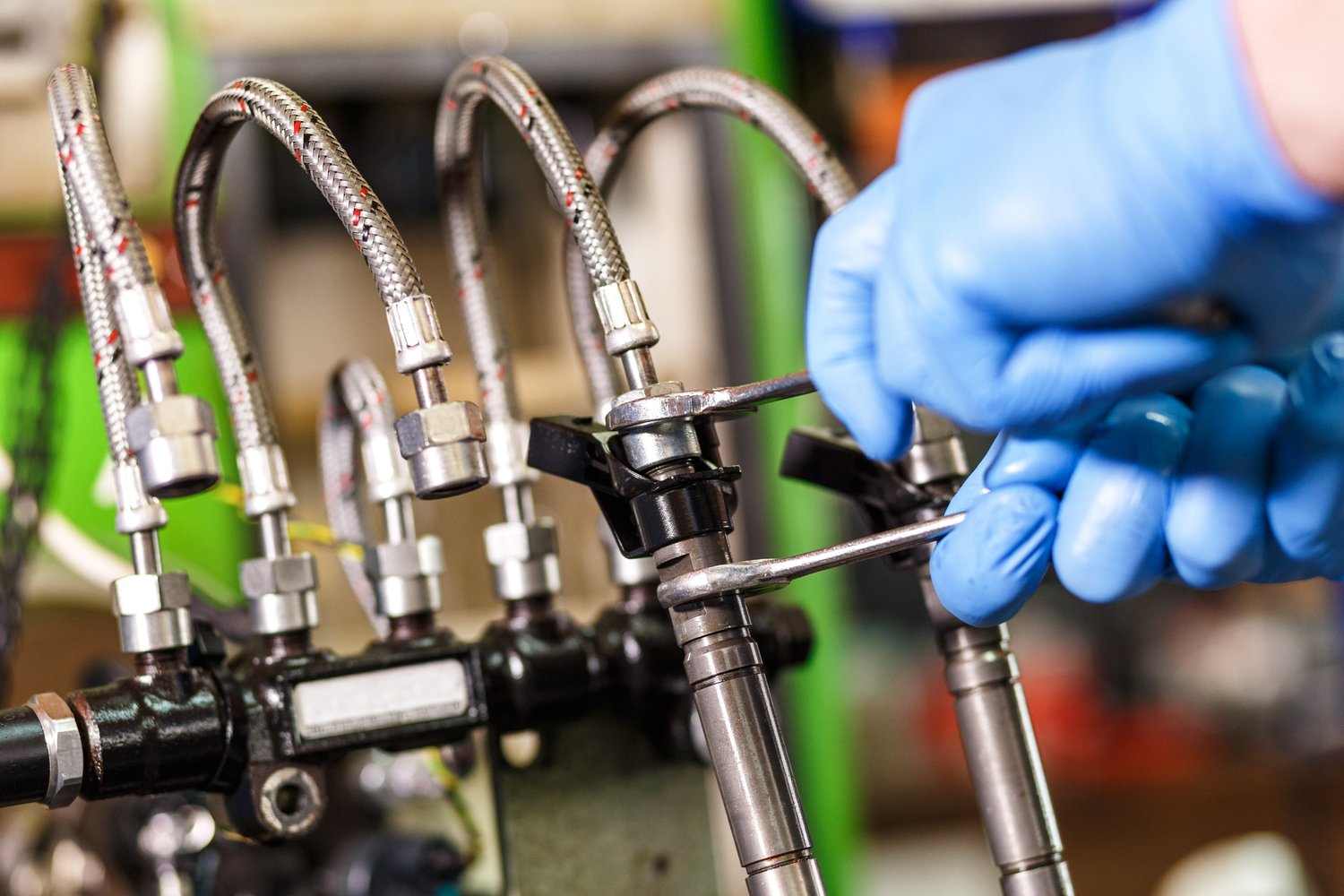

Nailers and fittings in plumbing and electrical work

Nailers are essential pneumatic tools for both plumbing and electrical professionals. They come in various types, including framing nailers, finish nailers, and brad nailers. Nailers and fittings are crucial for securing pipes, conduits, and electrical boxes. These tools can drive nails into hard-to-reach areas with precision and speed. Proper selection of nailers and fittings ensures efficient and reliable installations.

Other air tools for specialized tasks

Beyond nailers, there are numerous other air tools available for specific tasks. Pneumatic drills offer high torque and speed for drilling through various materials. Air-powered sanders provide smooth finishes on pipes and surfaces. Other air tools include impact wrenches for tightening or loosening bolts quickly. These specialized tools can significantly improve efficiency in electrical and plumbing projects.

Maintenance and safety considerations

Proper maintenance is crucial for the longevity and safety of pneumatic tools. Regular cleaning and lubrication are essential for optimal performance. Always inspect tools for wear and damage before use. Safety should be a top priority when operating pneumatic tools. Use appropriate personal protective equipment, including safety glasses and hearing protection. Ensure proper training for all personnel using these powerful tools.