Understanding electrical apparatus basics

Electrical apparatus forms the backbone of any electrical installation. These devices control, distribute, and protect electrical circuits. In residential settings, the average home contains 40-50 electrical apparatus components. Industrial facilities may have thousands. Electrical apparatus includes circuit breakers, switches, and relays. These components ensure safe and efficient power distribution. Understanding their functions is crucial for proper installation and maintenance. Electricians typically spend 3-5 years learning about various types of electrical apparatus.

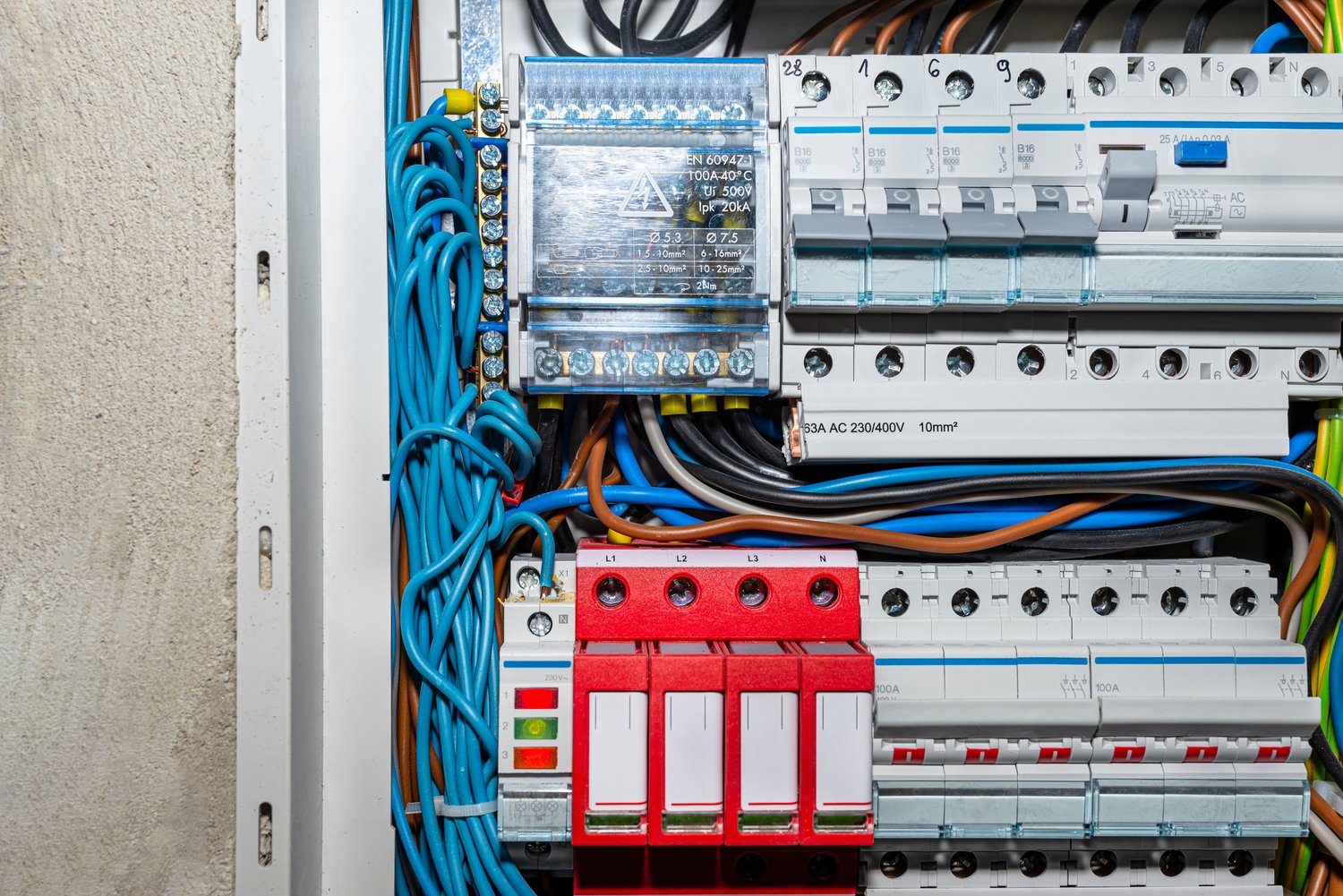

Modular apparatus offers flexibility in electrical systems. These components can be easily added or removed as needed. A typical modular system consists of 10-20 interchangeable units. This design allows for quick upgrades and repairs. Modular apparatus is particularly useful in commercial buildings. It enables easy expansion of electrical systems without major renovations. The modular approach can reduce installation time by up to 30% compared to traditional methods.

Control apparatus plays a vital role in managing electrical systems. These devices regulate power flow and equipment operation. A medium-sized factory might use 100-200 control apparatus units. They include contactors, timers, and programmable logic controllers (PLCs). Control apparatus ensures precise automation of industrial processes. It can improve energy efficiency by 15-25% in many applications. Proper selection of control apparatus is essential for optimal system performance.

Safety is paramount when working with electrical apparatus. Protective equipment such as insulated gloves and tools is essential. Electricians should always use voltage testers before handling live components. Regular maintenance can prevent up to 70% of electrical failures. It’s recommended to inspect electrical apparatus every 6-12 months. Keeping detailed records of all installations and maintenance is crucial for long-term safety and efficiency.

Energy efficiency is a growing concern in electrical installations. Modern Electrical apparatus can significantly reduce power consumption. High-efficiency transformers can decrease energy loss by 20-30%. Smart circuit breakers can monitor and optimize power usage in real-time. Implementing energy-efficient apparatus can lead to 10-15% savings on electricity bills. This approach not only reduces costs but also minimizes environmental impact.

Selecting the right modular apparatus

Choosing the correct modular apparatus is crucial for system reliability. Consider the required voltage and current ratings carefully. A typical residential panel might have 20-30 modular units. Commercial installations often require 50-100 or more. Modular apparatus comes in various sizes, typically ranging from 1 to 4 modules wide. Ensure adequate space in the distribution board for future expansions.

Quality is a key factor in modular apparatus selection. Look for products from reputable manufacturers with proven track records. High-quality modular apparatus can last 15-20 years or more. Cheaper alternatives might need replacement in 5-7 years. Consider the total cost of ownership, not just the initial price. Premium modular apparatus often offers better long-term value despite higher upfront costs.

Compatibility is essential when selecting modular apparatus. Ensure all components work seamlessly together. A mismatch can lead to system failures or reduced efficiency. Most manufacturers offer compatible product lines. Mixing brands may work but can lead to warranty issues. Always consult product specifications and installation guides. Proper installation can increase system lifespan by 30-40%.

Environmental factors play a role in modular apparatus selection. Consider temperature ranges, humidity levels, and potential exposure to contaminants. Industrial environments may require specially rated apparatus. IP ratings indicate protection levels against dust and water ingress. For example, IP65 rated devices are dust-tight and protected against water jets. Choosing the right protection can prevent 90% of environment-related failures.

Future-proofing is an important aspect of modular apparatus selection. Consider potential system expansions or upgrades. Allow for 20-30% additional capacity in your initial design. Smart modular apparatus with communication capabilities is becoming increasingly popular. These devices can integrate with building management systems. They provide real-time data and remote control options, improving overall system efficiency by up to 25%.

Optimizing control apparatus for efficiency

Proper selection of control apparatus is crucial for system efficiency. Consider the specific requirements of your application. Industrial processes may need specialized control apparatus. A typical production line might use 10-15 different types of control devices. These include motor starters, variable frequency drives, and PLCs. Matching the control apparatus to the load can improve energy efficiency by 20-30%.

Automation plays a key role in optimizing control apparatus. Programmable logic controllers (PLCs) can manage complex systems efficiently. A medium-sized PLC can handle 100-200 input/output points. This allows for precise control of multiple processes simultaneously. Automated systems can reduce human error by up to 80%. They also enable 24/7 operation without fatigue, increasing productivity.

Energy management is a critical function of modern control apparatus. Smart controllers can monitor and adjust power consumption in real-time. They can reduce energy waste by 15-25% in many applications. Features like soft starting and variable speed control are particularly effective. These technologies can extend equipment life by reducing mechanical stress. Implementing energy-efficient control strategies can lead to significant cost savings over time.

Maintenance considerations are important when selecting control apparatus. Choose devices with clear diagnostic features. Many modern controllers offer remote monitoring capabilities. This can reduce downtime by allowing quick identification of issues. Predictive maintenance algorithms can prevent up to 70% of unexpected failures. Regular software updates ensure optimal performance and security. Plan for a maintenance schedule that includes checks every 3-6 months.

Integration with other systems enhances the effectiveness of control apparatus. Modern control devices often support various communication protocols. These include Modbus, Profibus, and Ethernet/IP. A well-integrated system can improve overall efficiency by 10-15%. It allows for centralized monitoring and control of multiple processes. Consider future expansion needs when selecting communication-enabled control apparatus. Scalability can save significant costs in the long run.

Leveraging control and measurement apparatus for precision

Control and measurement apparatus are essential for accurate system monitoring. These devices provide crucial data for process optimization. A typical industrial setup might use 50-100 measurement points. Common types include temperature sensors, pressure transducers, and flow meters. High-precision measurements can improve product quality by up to 30%. They also help in identifying inefficiencies in the production process.

Calibration is critical for maintaining accuracy in control and measurement apparatus. Regular calibration ensures reliable data and compliant operations. Most instruments require calibration every 6-12 months. Some critical applications may need more frequent checks. Proper calibration can reduce measurement errors by up to 90%. It’s essential to maintain detailed calibration records for quality assurance and regulatory compliance.

Data logging capabilities enhance the value of control and measurement apparatus. Modern devices can store thousands of data points. This allows for trend analysis and predictive maintenance. Data loggers with wireless connectivity offer real-time monitoring. They can alert operators to anomalies instantly. Analyzing historical data can lead to process improvements, potentially increasing efficiency by 10-15%.

Environmental factors affect the performance of control and measurement apparatus. Temperature fluctuations can cause measurement drift. Vibration and electromagnetic interference can also impact accuracy. Choose instruments rated for your specific operating conditions. Proper shielding and isolation can improve measurement stability by up to 50%. Regular environmental assessments help ensure optimal performance of these sensitive devices.

Integration with control systems maximizes the benefits of measurement apparatus. Closed-loop control based on real-time measurements can significantly improve process stability. This approach can reduce variability in product quality by 20-30%. Advanced control algorithms like model predictive control (MPC) rely on accurate measurements. They can optimize complex processes, potentially saving 5-10% in energy and raw materials. Always consider the compatibility of measurement devices with your existing control infrastructure.