In the world of electrical systems, the often-overlooked task of labeling an electrical service panel plays a critical role in maintaining both safety and functionality. With the increasing complexity of modern electrical setups, having a system in place for precise and clear circuit identification isn’t just a convenience—it’s a necessity. This article delves into the best practices for labeling, ensuring your electrical system is both efficient and compliant with industry standards.

- Proper labeling minimizes electrical hazards and simplifies maintenance procedures.

- Discover practical guidelines for creating clear and durable electrical service panel labels.

- Learn about the latest tools and techniques that enhance the labeling process for better circuit identification.

- Implementing these methods can significantly improve your system’s safety and reliability.

By following the strategies outlined in this article, you’ll gain valuable insights into optimizing your electrical service panel, making it easier to manage and maintain. Whether you’re a professional or a DIY enthusiast, investing time in understanding these techniques will pay dividends in safety and system efficiency.

Why Accurate Electrical Service Panel Labels Are Essential for Proper Circuit Identification Methods

Accurate labeling of electrical service panels plays a critical role in promoting safety and efficiency in residential and commercial electrical systems. By clearly identifying circuits, you significantly reduce the risk of electrical hazards, which can lead to dangerous situations. Furthermore, proper circuit identification is crucial for facilitating maintenance tasks, enabling electricians and homeowners to quickly locate and address issues without unnecessary trial and error.

Compliance with safety standards is another compelling reason to ensure your electrical service panel labels are precise. Local building codes and electrical safety regulations often mandate specific labeling practices, and failure to adhere to these could result in costly fines or liabilities.

A well-organized panel with detailed circuit information enhances the management and operational reliability of your electrical systems. It allows for efficient troubleshooting and reduces downtime, whether it’s in a residential setting or a busy commercial environment. Embracing accurate labeling practices ensures both the functionality and longevity of your electrical system infrastructure.

Best Practices for Creating Electrical Service Panel Labels

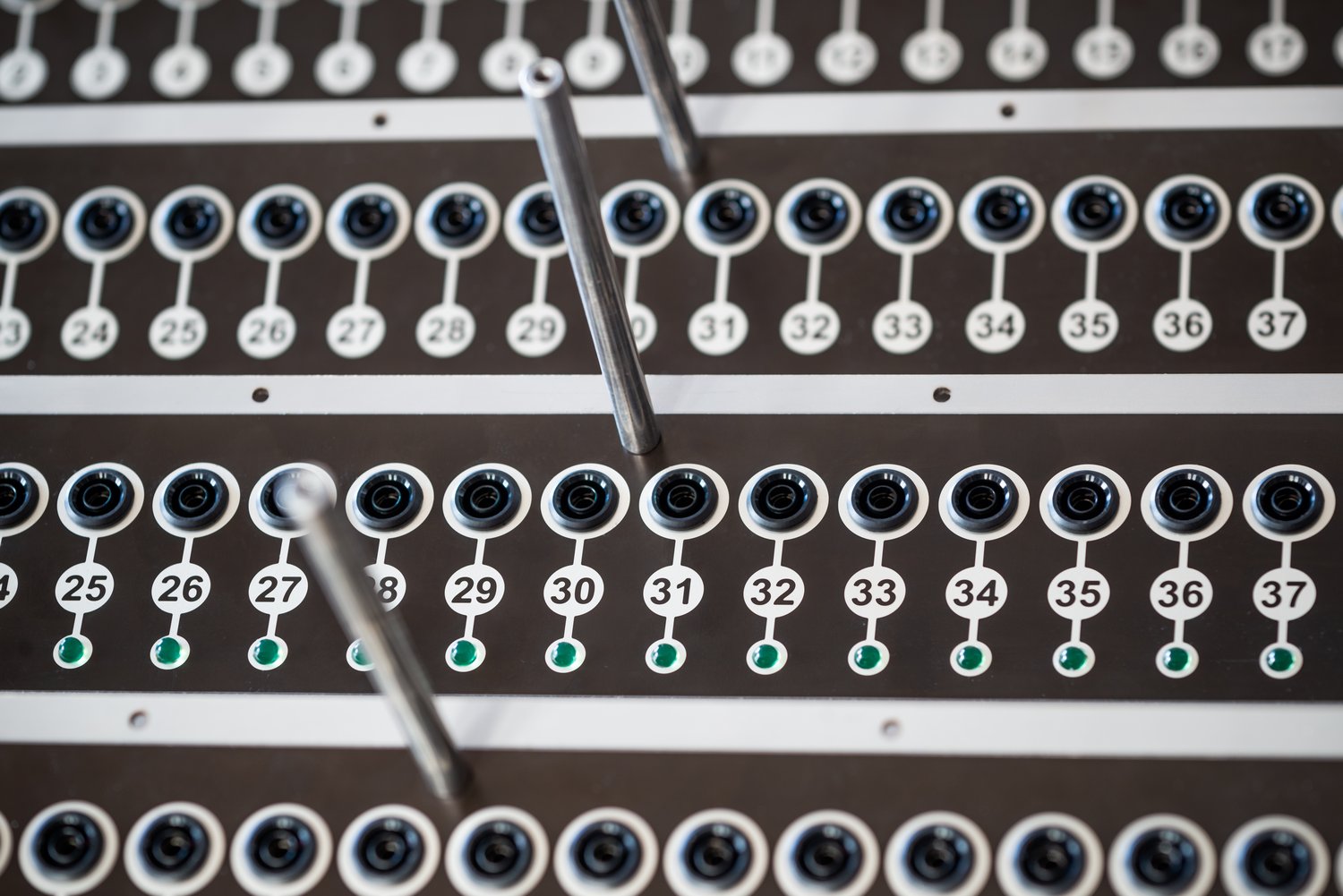

Crafting precise and clear electrical service panel labels is a straightforward yet essential task that enhances circuit identification and overall system management. Begin by utilizing clear, concise descriptions. This means avoiding technical jargon when possible and opting for simple language that accurately conveys the circuit’s purpose or location.

The durability of the labeling material is also paramount. Invest in high-quality, weather-resistant labels that can withstand environmental factors such as humidity or temperature changes. This ensures your labels remain legible over time, reducing the need for frequent replacements.

Organizing labels in a logical and consistent layout is another key practice. Consider the flow and approachability of the panel. Start from the top left and move downward in a sequential manner. This methodical arrangement aids in quick identification and efficient troubleshooting.

By adhering to these best practices, you enhance the accuracy and effectiveness of your electrical service panel labels, ensuring your electrical systems are both safe and easy to navigate.

Tools and Techniques to Enhance Electrical Service Panel Labels: Proper Circuit Identification Methods

In the realm of electrical service panels, clarity and precision in labeling are paramount for maintaining safety and efficiency. Utilizing the right tools and techniques can significantly improve the process of creating labels that are both practical and enduring. By employing a combination of digital and physical resources, you can ensure that your circuit identification is as accurate as possible.

One of the most effective ways to enhance your labeling process is through the use of digital labeling software. These applications provide a streamlined approach to designing and organizing labels, allowing you to input detailed descriptions and generate clear, professional designs. Some software solutions enable easy updates and modifications, accommodating changes in your electrical system without requiring a complete re-labeling.

In addition to digital tools, high-quality label printers play a crucial role in producing durable and legible labels. Choose printers that can handle a variety of paper types and adhesive materials to ensure that your labels withstand environmental factors such as heat and moisture. It’s also beneficial to select printers with adjustable font sizes and symbols to suit different circuit descriptions.

Furthermore, physical tools like label makers with thermal printing capabilities offer a simple, yet effective way of creating long-lasting labels. These devices are particularly useful for on-site adjustments, allowing you to instantly produce new labels as needed. The use of laminated tapes and UV-resistant inks can further extend the lifespan of your labels, making them resistant to fading or damage over time.

Stencil kits and engraving tools are additional options for ensuring enduring and readable labels. Stencils offer a manual method for labeling, useful in situations where electrical service panels are exposed to extreme conditions. Engraving adds an extra layer of permanence, especially for critical circuits that require unmistakable identification.

Incorporating these tools and techniques into your labeling process not only enhances the clarity of your electrical service panel labels but also contributes to overall electrical safety and accessibility. By using a comprehensive approach to circuit identification, you can maintain a well-managed and secure electrical system.

Frequently Asked Questions about Electrical Service Panel Labels

Why is accurate labeling of electrical service panels important?

Accurate labeling reduces electrical hazards, facilitates maintenance, and ensures compliance with safety standards.

What are the best materials for electrical panel labels?

- Durable materials such as vinyl or polyester are preferred.

- These materials resist moisture and wear over time.

How can I organize panel labels effectively?

Use clear and consistent descriptions and a logical layout that aligns with the panel’s circuit arrangement.

Are there digital tools available for electrical panel labeling?

Yes, software applications offer digital solutions for designing and printing labels accurately.

What common mistakes should I avoid in panel labeling?

- Avoid using vague descriptions.

- Ensure labels are legible and correctly positioned.