Understanding Cables and Wires

Cables and wires are fundamental components in electrical systems. They come in various types, each designed for specific applications. Electrical conductors are typically made of copper or aluminum. Copper offers better conductivity but is more expensive. Aluminum is lighter and cheaper, yet less conductive. The choice between these materials depends on the project requirements and budget constraints. Cables and wires are available in different gauges, measured by the American Wire Gauge (AWG) system. Lower AWG numbers indicate thicker wires, suitable for higher current loads. It’s crucial to select the appropriate gauge to ensure safety and efficiency in your electrical installations.

Insulation is another critical aspect of cable selection. PVC (polyvinyl chloride) is a common insulation material, offering good electrical properties and fire resistance. XLPE (cross-linked polyethylene) provides superior heat resistance and durability. For outdoor applications, UV-resistant insulation is essential to prevent degradation from sunlight exposure. Some cables feature multiple layers of insulation for enhanced protection. The voltage rating of a cable indicates its maximum operating voltage. Always choose cables with ratings that exceed your system’s requirements to ensure safety margins.

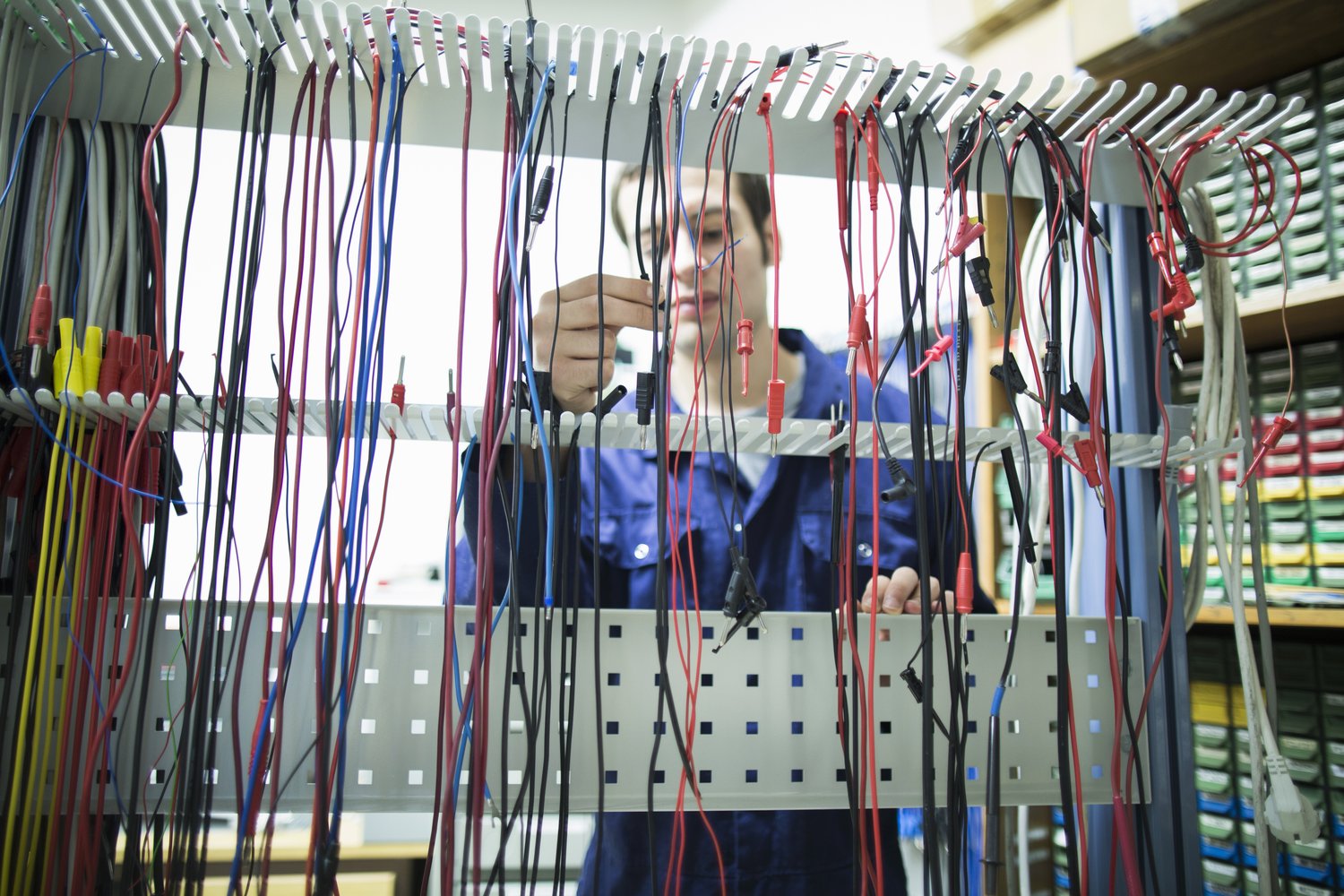

Cable flexibility is an important consideration for many installations. Stranded conductors offer greater flexibility compared to solid cores. This makes them ideal for applications requiring frequent movement or tight bends. However, solid core cables provide better stability for fixed installations. The number of conductors in a cable varies based on the application. Single-core cables are used for individual phases, while multi-core cables combine multiple conductors within a single sheath. This can simplify installation and reduce costs in complex wiring systems.

Selecting Installation Cables

Installation cables are specifically designed for fixed wiring in buildings. These cables must comply with local electrical codes and standards. The most common types include NYM, NYY, and YDYP cables. NYM cables are suitable for indoor use, featuring a PVC sheath and insulation. They can be installed in dry and damp environments, making them versatile for residential and commercial applications. NYY cables are designed for outdoor and underground installations, with enhanced moisture resistance.

Installation cables come in various conductor configurations. Single-core cables are used for individual circuits, while multi-core cables combine multiple conductors for more complex systems. The color coding of conductors follows standardized schemes to ensure proper identification. For example, in Europe, brown typically indicates a live wire, blue for neutral, and green/yellow for ground. Always verify local color coding standards before installation to avoid confusion and potential hazards.

When selecting installation cables, consider the environment where they will be used. Cables for outdoor use require UV resistance and weather protection. For installations in areas with high electromagnetic interference, shielded cables may be necessary. Fire-resistant cables are crucial for critical systems and escape routes in buildings. These cables maintain circuit integrity for a specified period during a fire, allowing essential systems to continue functioning. Always consult local building codes to ensure compliance with fire safety regulations.

Benefits of YDYP Flat Multi-core Cables

YDYP flat multi-core cables are popular choices for many electrical installations. These cables feature multiple conductors arranged in a flat configuration. The flat design offers several advantages over round cables. They are easier to route along walls and surfaces, providing a neater appearance in visible installations. The compact profile also allows for easier installation in tight spaces, such as behind baseboards or in shallow wall cavities. YDYP cables typically have a PVC sheath, offering good protection against mechanical damage and environmental factors.

The multi-core nature of YDYP cables simplifies wiring for circuits requiring multiple conductors. This can reduce installation time and costs compared to running individual cables. YDYP flat multi-core cables are available in various conductor counts, typically ranging from 2 to 5 cores. The most common configurations are 3-core (for single-phase circuits with ground) and 5-core (for three-phase circuits with neutral and ground). The flat design also facilitates easier separation of conductors at termination points, simplifying connections to devices and junction boxes.

When using YDYP cables, it’s important to consider their current-carrying capacity. This depends on factors such as conductor size, insulation type, and installation method. For example, a 3×1.5mm² YDYP cable can typically carry up to 16 amperes when installed in free air. However, this capacity may be reduced when installed in conduits or bunched with other cables. Always refer to manufacturer specifications and local electrical codes to determine the appropriate cable size for your application. Proper installation techniques, such as avoiding sharp bends and excessive tension, are crucial to maintain the cable’s integrity and performance over time.